Project Description

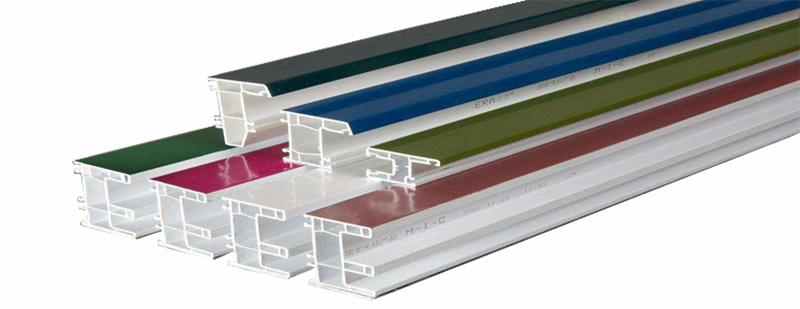

UPVC VERTICAL HINGED WINDOW SYSTEM

UPVC profiles as a new generation of door and window materials, with anti-aging, corrosion resistance, high strength, non-deformation, flame retardant self-extinguishing, color harmony and other characteristics, widely used in building doors and windows and indoor and outdoor decoration, beautifying the environment, protecting forest resources, alternative to aluminum, wood ideal building products, our company’s plastic steel doors and windows because of its wind pressure resistance. High degree, air tightness, good water tightness, air, rain water permeability is small, low heat transfer coefficient and energy-saving insulation, sound insulation and other advantages can be highly recognized by customers.

Advantages

Insulation performance: UPVC doors and windows heat transfer coefficient is 1/1250 of the ordinary aluminum alloy doors and windows, and the energy dissipation of the house, only 30% aluminum alloy doors and windows, comprehensive energy saving 30% – 50%.

Sound insulation and noise reduction: the use of hollow glass UPVC doors and windows can reduce indoor noise to 1/3 of the outdoor, maintain around 30 decibels, so that you can live in a downtown area can also have quiet

Water and air tightness :UPVC doors and windows adopt multi-layer sealing design and scientific flume, which greatly improves water tightness and air tightness, and overcomes the defects of other traditional doors and windows.

Anti wind pressure: the use of steel lining enhances the steel property of UPVC doors and windows, making it more solid and firm.

Affinity: elegant, beautiful, glossy and durable, without painting and maintenance.

| UPVC-V-65 | UPVC-V-60-1 |

| UPVC-V-60-2 | UPVC-V-60-3 |

Techonlogy

UPVC DOORS AND WINDOWS MIN PROCESS OPERATION

| PROCESS OPERATION | REQUIREMENTS | EQUIPMENT | REMARKS |

| Profile storage | Products should be stored in a cool, ventilated warehouse,

level stack, height can not exceed 1.5M, to avoid direct sunlight |

||

| Cutting of main profiles | The main profiles are obliquely cut 45 degrees at both ends,

V-shaped mouth, pointed end, etc. Choose qualified profiles, cutting size and cutting accuracy should be controlled when cutting. |

Double angle saw, V saw | The welding allowance for profile

welding is 3mm per end. |

| Hardware process hole | Bottom frame, cross bar milling and flume, milling keyhole,

hardware hole. |

Milling machine, imitation milling | |

| Cutting of steel lining | According to cutting stock cutting, grinding ends fly. | Grinding machine | |

| Steel lining assembly | Insert the steel lining into the frame and fan section,

and screw it as required. |

Bench drill, electric drill, self tapping screw | |

| Woolen top assembly | The three border of a fan | manual | |

| Welding | Door and window frames and fans are welded by

welding machines. |

Welding machine | Adjusting the best welding parameters

(Temperature, time and pressure) |

| Cleaning weld | Clean up internal and external welds. | Angle milling machine, pneumatic milling cutter | |

| Cutting of auxiliary profiles | Layering, the closure of the sliding window,

and the splicing of the profiles. |

Glass layering saw, single head saw, double headed saw | The ends of the glass layering are cut into 45 degrees,

and the ends of both ends are opened. |

| EPDM assembly | The EPDM of the glass layering is K shaped,

and the main section of the frame fan is O shaped. |

Roller, scissors | |

| Hardware assembly | Install hardware according to contract and drawing requirements. | Electric and pneumatic tools, cutting knives,

self tapping, imitation milling. |

|

| Glass assembly | Install glass block and fix glass strip. | Platform, glass block | |

| Finished product inspection and packing | General inspection of door and window products,

certificate of conformity, matching package |

Packing with soft materials. | |

| Warehousing | In accordance with specifications, varieties,

or classification of projects placed, vertical neat, angle not less than 70 degrees, away from the heat source more than 1 m |

Door and window placing rack | When placed, hardware should be staggered to avoid damage. |

Window & Door Solution