Project Description

Description

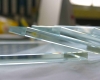

SSM GLASS—ULTRA CLEAR GLASS is the first enterprise product the ultra clear glass in CHINA , relying on PPG production engineering , has produced 1.8 MM to 25 MM and 11500 MM long , and through technical innovation, research and development of high-end “to pure” boutique Ultra clear glass.The products feature high security: low spontaneous breakages,, since application never spontaneous breakages.

Applications

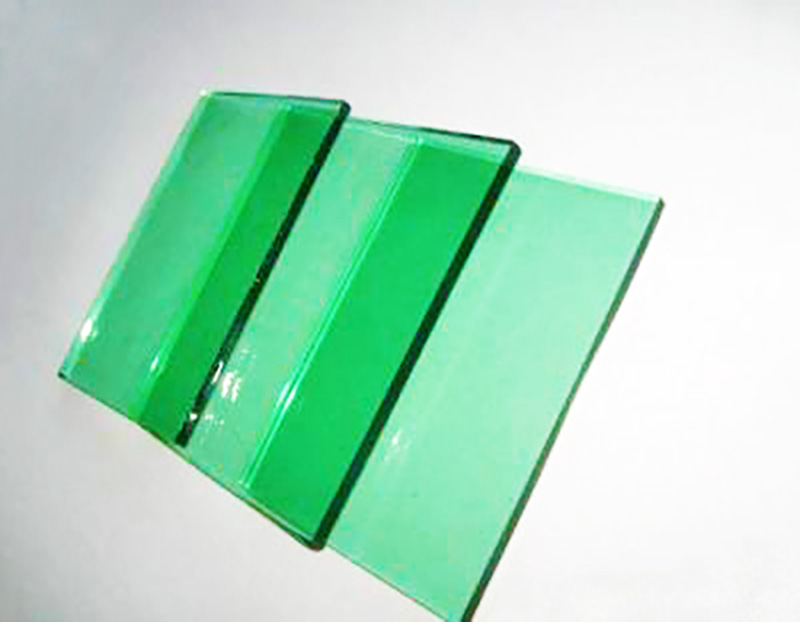

With glittering and translucent, high quality and elegant features, the glass family “crystal Prince” is called. It has excellent physical, mechanical and optical properties, and can be processed like other high quality float glass. The unparalleled superior quality and product performance make the ultra white glass have a broad application space

SSM GLASS—ULTRA CLEAR GLASS can be used extensively in applications such as

| Exterior decoration of the Buildings | Interior decoration of the Buildings |

| Furniture products | Bathroom products |

| Showcases | Industrial products |

| Arts and Crafts | |

Advantages

High safety:

Low spontaneous breakages, until now there is no spontaneous breakages.

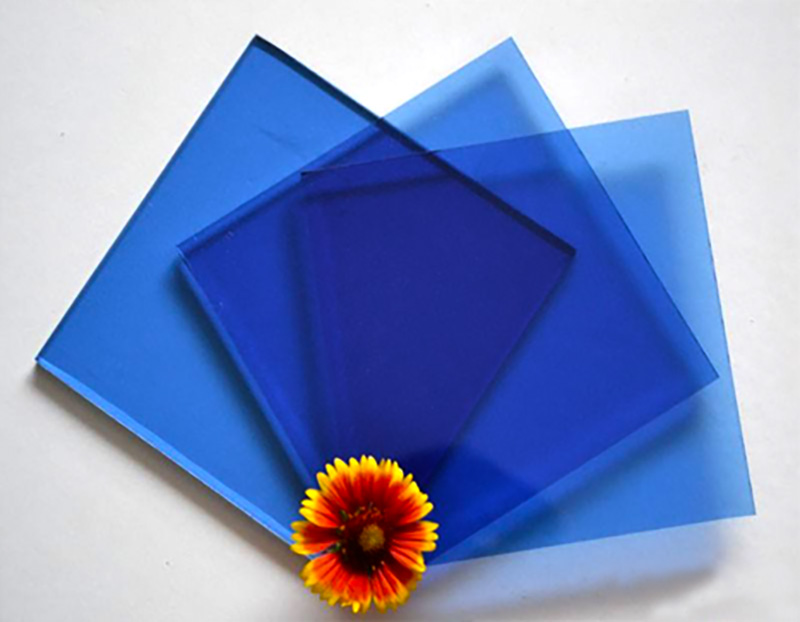

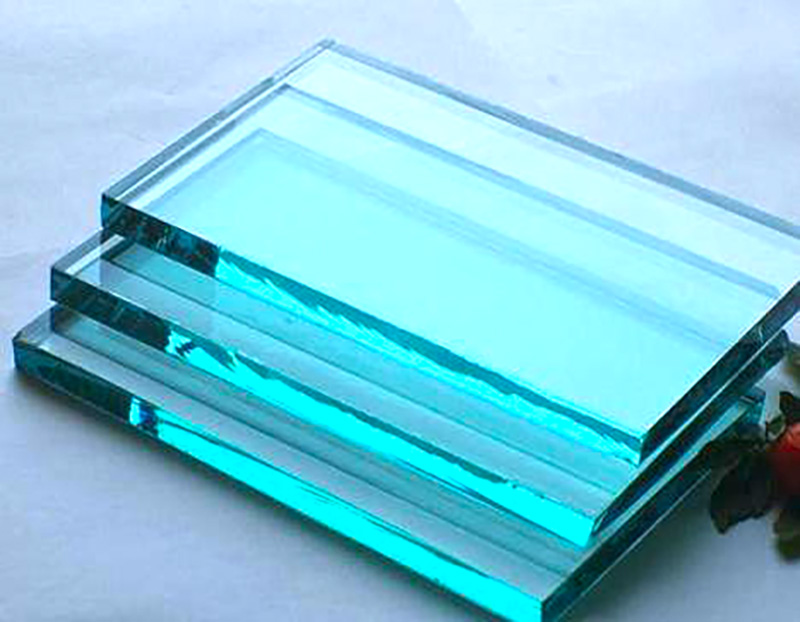

High transmittance:

Visible light transmittance near 92%, 6% higher than clear float glass.

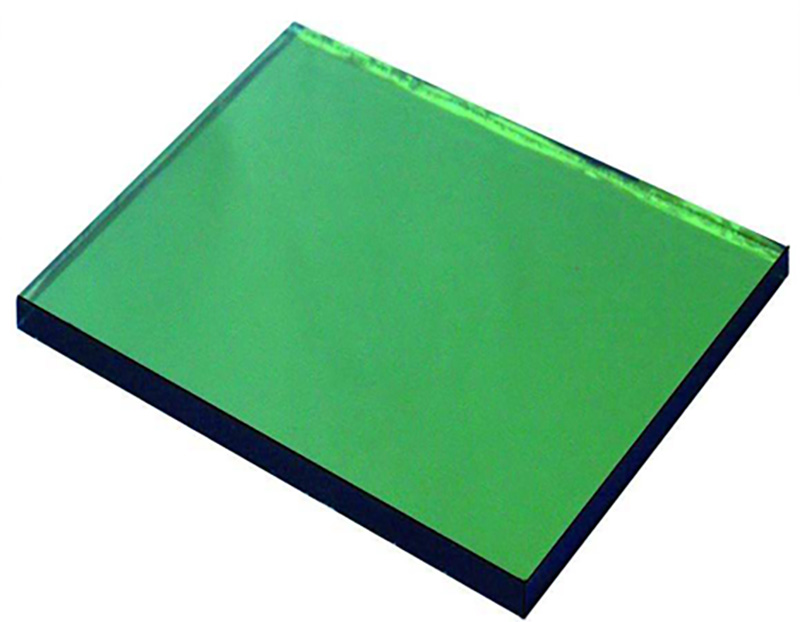

High aesthetics:

More beautiful than clear float glass, with a jewel-like blue edge.

Friendly environment:

Has obtained certificates of CE, SGS, REACH.

Techonlogy

THERMOTECHNICAL AND OPTICS PERFORMANCE

| hickness | visible light | Solar Radiant Coefficient | Shading Coefficient | U value | Sound | UV Penet | |||||||

| (MM) | Insulation | ration | |||||||||||

| Trans | Refle | Direct | Refle | Absorb | Total | Short | Long | Total | (W/m2K) | Rm (dB) | Rw (dB) | ||

| mittance | ctivity | Penetration | ctivity | Trans | Wave | wave | |||||||

| 3 | 91.50% | 8% | 91% | 8% | 1% | 91% | 1.05 | 0.01 | 1.05 | 5.8 | 26 | 30 | 76% |

| 3.2 | 91.50% | 8% | 91% | 8% | 2% | 91% | 1.03 | 0.01 | 1.05 | 5.8 | 26 | 30 | 75% |

| 4 | 91.40% | 8% | 90% | 8% | 2% | 91% | 1.03 | 0.01 | 1.05 | 5.8 | 27 | 30 | 73% |

| 5 | 91% | 8% | 90% | 8% | 2% | 90% | 1.03 | 0.01 | 1.03 | 5.8 | 29 | 32 | 71% |

| 6 | 91% | 8% | 89% | 8% | 3% | 90% | 1.02 | 0.01 | 1.03 | 5.7 | 29 | 32 | 70% |

| 8 | 91% | 8% | 88% | 8% | 4% | 89% | 1.01 | 0.01 | 1.02 | 5.7 | 31 | 34 | 68% |

| 10 | 91% | 8% | 88% | 8% | 4% | 89% | 1.01 | 0.02 | 1.02 | 5.6 | 33 | 36 | 66% |

| 12 | 91% | 8% | 87% | 8% | 5% | 88% | 1 | 0.02 | 1.01 | 5.5 | 34 | 37 | 64% |

| 15 | 90% | 8% | 86% | 8% | 6% | 87% | 0.99 | 0.02 | 1 | 5.5 | 35 | 38 | 61% |

| 19 | 90% | 8% | 84% | 8% | 7% | 86% | 0.97 | 0.02 | 0.99 | 5.5 | 37 | 40 | 59% |

| 22 | 89.60% | 8% | 82% | 8% | 9% | 85% | 0.95 | 0.02 | 0.97 | 5.5 | 38 | 43 | 58% |

| 25 | 89% | 8% | 81% | 8% | 9% | 84% | 0.93 | 0.02 | 0.95 | 5.5 | 39 | 45 | 56% |

PHYSICAL PARAMETERS

| Elasticity Modulus | 73.1Gpa |

| Rupture Modulus(Tensile Strength-ultimate) | 41.4 Mpa |

| Knoop Hardness | 456kgf/mm2 |

| Density | 2.5076 g/cm3 |

| Linear Coefficient of Expansion 20-300 ℃ | 9.28×10-6/℃ |

| Linear Coefficient of Expansion 20-450 ℃ | 9.75×10-6/℃ |

| Transformation Temperature | 556℃ |

| Intenerate Temperature or Yield Point | 606℃ |

| Softening Point | 710℃ |

| Annealing Point | 547℃ |

| Strain Point | 513℃ |

| High Temperature Viscosity log2 | 1392℃ |

| High Temperature Viscosity log3 | 1152℃ |

| High Temperature Viscosity log4 | 996℃ |

| Liquid Phase Temperature | 1008℃ |

| Spontaneous breakages Rate | 0.00% |

Float Glass